Printing on cover materials

Compared with the past, many printing techniques are now available for textile cover materials, and combining different techniques on the same binding is perfectly possible. Below is a brief overview of techniques that lend themselves best for our cover materials.

Home / Products / Cover Materials / Printing on Cover Materials

PRINTING TECHNIQUES

The large selection of binding materials available enables the designer to give a hard cover book the ‘packaging’ it deserves. Over time, linen has definitely proved its worth as a binding material. For many book-lovers and readers, a book simply must be bound in linen to be attractive, strong and valuable. Van Heek Textiles has done much to give designers or publishers a real choice from the various types of linen in contemporary colours. One of linen’s advantages over other binding materials is that it is a natural product, with a distinct feel and texture after weaving

Creative designers and inventive bookbinders have succeeded in producing a myriad of beautiful and surprising bindings. Matching the design to the available materials, linen, foil, boards, headbands, bookmarks, end-papers, and selecting the appropriate stamps and printing techniques is an exciting challenge, often achieved in close collaboration between designer and binder. And when special print runs call for this, the time-honored methods of manual craftsmanship will not be shunned.

Traditional techniques

Offset printing

A high-quality offset print can be achieved on binder’s cloth, depending on the type of linen. The surface should not be too rough, and the sheets must lie perfectly flat so that feeding in, positioning and transport through the press occurs seamlessly. Linen can be treated with a coating specifically designed for offset printing. While this facilitates the printing process, it may reduce the tactile structure of the linen.

Coated linen is very suitable for books, as well as stationery items such as ring binders, notebooks and other high-use products. The versatility of offset printing also allows for the use of spot colours — for example, corporate logo elements — on the binding in precisely the intended shade.

When printing by offset lithography on Brillianta, Brillianta Calandré, Finesse, Natuurlinnen, and other materials, we recommend using oxidative-drying inks designed for absorbent substrates such as natural fibres. These inks should be used with as little water as possible.

For Printex, Imprimex and Reprotex, which were formulated for synthetic substrates (i.e. non-absorbent), the same advice applies: use oxidative-drying offset inks with minimal water. We also advise using a multi-dryer (2–5 %). Our offset materials are compatible with waterless offset as well.

For all of our materials, we recommend allowing the material to acclimatise in the printing room for 24 hours in its original packaging. The output stack of sheets should not be too high. Because the ink dries by oxidation, this stack height should be approximately one third of the standard height for ordinary substrates. Before commencing production, carry out a number of test prints to determine the optimal printing pressure and ink feed for the specific linen substrate.

If ink coverage is inadequate, optimisation can be achieved by increasing pressure or supplying more ink. We recommend using soft printing blankets to ensure better contact with the substrate.

Screen-frequency guidelines:

- For oxidative-drying inks on non-absorbent substrates: maximum 70 lines/cm

- For waterless offset inks: maximum 120 lines/cm

Upon request, we can cut linen from the roll into sheets in the specified format. We can do this for large print runs from extremely large production rolls, which means the linen lies flat after it has been cut into sheets.

Example: In offset printed Printex

OFFSET UV PRINTING

UV offset printing employs special UV lamps to cure (dry) the ink immediately as it is printed. Because the ink dries so quickly, it cannot spread, resulting in very sharp print definition. This technique is well suited to large print runs on presses where each of the four colours is applied in a separate tower.

Offset UV printing works best on smooth, coated substrates such as Buckram Premium, Buckram Light, Fancy, Metallium, Finesse, etc. On coarser fabrics with a more open texture e.g., Halflinnen Dark or Regina the ink may be absorbed too deeply, leading to blurred prints. For this reason, denser or coated materials are recommended for UV offset printing.

Thanks to a specific UV-compatible coating, Buckram Premium in white is particularly well suited for UV printing.

Screen printing

Screen printing involves forcing ink through a stencil onto the material. A photographic stencil is applied to a fabric screen (such as silk, nylon or steel mesh) stretched over a frame. The material to be printed (e.g. linen) is positioned so that registration is accurate when applying multiple colours. A squeegee spreads the ink across the stencil, forcing it through the mesh and onto the substrate.

Special ink is used for screen printing on linen, which typically has excellent adhesive properties. The key advantage of screen printing is its versatility; the print can be applied to nearly any surface, and exquisite results can be achieved. However, screen printing inks take a long time to dry: each sheet or binding must be laid out individually on drying racks, demanding considerable workspace and labour.

This method is especially suitable when a hand-drawn or painted illustration must be reproduced. Due to the thick ink layer, the original style can be closely imitated. However, the thickness limits fine-screen detail and makes it less suitable for extremely delicate elements. To ensure accurate placement, designers may choose to print bindings after they have been assembled.

When the front cover, back cover and spine use boards of different thickness, height discrepancies may arise; these can be compensated by adjusting the press table accordingly.

hot foil stamping

Hot-foil stamping applies an image or text to a book binding, box, or album using a heated stamp under high (or very high) pressure. The embossing stamp deforms the linen and board locally while transferring the foil, producing a relatively deep impression.

The clarity of the stamped design depends on several factors: the fabric’s smoothness and density, the type of foil, stamp pressure, the stamp’s temperature, and the contact time. If the embossing stamp has areas of varying depth, a relief effect can be created. It is important that the board has a firm, smooth surface.

For very light-coloured linens, a similarly light-coloured board should be used underneath to enhance the impression. Success in foil printing depends on good foil release, sharp imprint, and strong adhesion between the foil and the cloth.

The choice of die is also crucial: magnesium, copper or brass are all used. As a general rule, harder metals maintain sharper bevels for longer. Magnesium dies are cost-effective for short runs but may lose their bevel sharpness; copper dies are more robust, while brass dies, though more expensive, provide very crisp, lasting impressions.

Various effects can be achieved by applying different foils, coloured foils with matt or high-gloss finish, or metallic foils (gold, silver) in matt, satin or high-gloss. On linen, satin or matt metallic foils often produce more elegant results than high-gloss foils.

For example, a heavy impression in matt foil can flatten the linen’s structure, creating a smooth base. Once this is set, you can overprint a sharply defined title in gold or silver foil. Doing this later avoids the risk of letter-filling that might happen if you printed directly on fabric. Using a stamp where the text is cut out allows for relief printing. Gold and silver foils generally give better coverage, sharper lines, and superior scratch resistance than coloured foils.

Foil printing is widely regarded as environmentally friendly: there are no solvents or dust, and used foil remnants can be discarded with normal waste. Paper products printed with foil can still be recycled.

Visit the Download Centre for a detailed foil stamping guide >

Blind stamping and embossing

Blind stamping can be used as a standalone technique, or as an alternative to foil. It is particularly effective for titles, large blocks, linear motifs or ornaments on linen bindings. Many illustrated or art books that use linen bindings also have a blind-stamp on the cover so that the book remains identifiable even without a dust jacket.

Blind stamping may also serve as a pre-treatment: pressing specific areas of raw linen to smooth them, enabling fine text or small illustrations to be printed later. We particularly recommend this for ribbed fabrics like Regina, or coarser textiles such as Halflinnen Dark.

In some cases, an illustration already printed on paper or a self-adhesive material needs to be applied to the binding. Here, blind stamping can be used to create a recessed area (‘at depth’) where the label is applied. The same types of stamps used in foil printing apply, and for embossing you typically need a patrix and a matrix (or stamp and counterpart).

Digital printing techniques

Dry toner printing

This is one of the most widely used techniques. It is cost-effective and suitable for both low and high-volume runs. However, the variety of dry-toner printers (and their differing capabilities) means it is difficult to give uniform advice.

In general, better definition is achieved on smoother fabrics such as Finesse, while coarser materials like Natuurlinnen deliver less detail, though some designers intentionally combine coarse textures with prints for more character.

We advise printing test samples and assessing the quality before committing to large print runs.

UV printing

Digital UV printing uses special UV lamps to cure (dry) the ink immediately. Because the ink doesn’t have time to spread, it yields excellent definition. Another advantage of this technique is its versatility: beyond simple text, you can produce fine shapes and combine them with glossy, metallic or other embellishment effects.

Although highly versatile, this method is most effective on smooth, coated substrates e.g., Buckram Premium, Buckram Light, Fancy, Metallium, Finesse, etc. On open-textured or coarse fabrics (e.g. Halflinnen Dark or Ecojeans), the ink may seep in, leading to blurred edges. For this reason, denser or coated materials are recommended. Nevertheless, rapid technological advances are making a wider range of substrates available for UV printing.

Thanks to a UV-compatible coating, Buckram Premium in white is particularly well adapted for UV digital printing.

UV printing is one of the more environmentally friendly digital techniques, producing very few volatile organic compounds (VOCs), odours or heat emissions.

Solvent inkjet printing

Solvent printing is well suited to high-volume, low-cost runs. While it typically yields lower resolution than UV printing, it remains popular for textile cover materials. However, many users are switching away from this method because solvent inks can be aggressive and are less environmentally friendly than latex or UV inks.

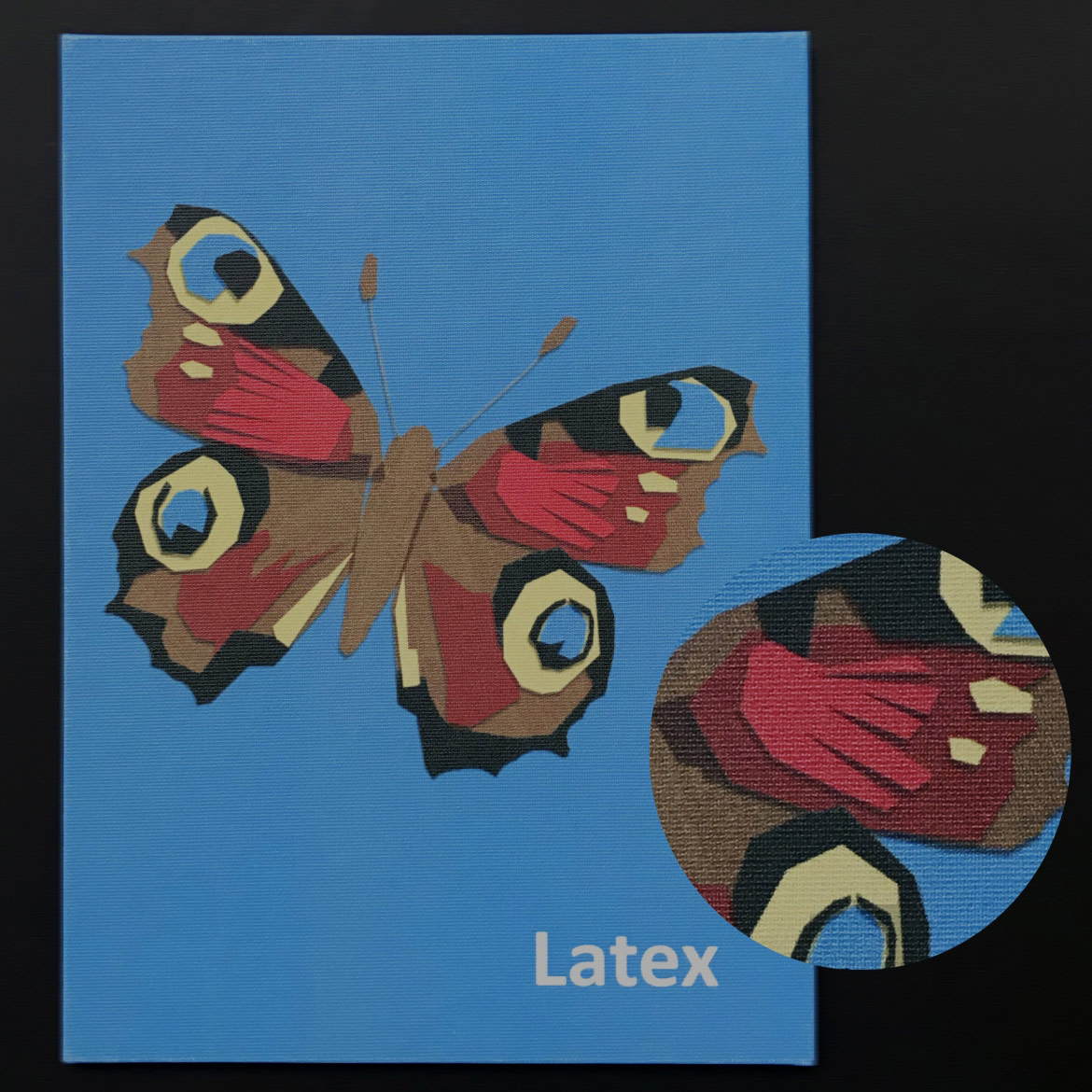

Latex inkjet printing

Latex printers support a wide range of media, making them highly suitable for transferring artwork to textile cover materials. As the ink dries within the printer, the printed fabric roll can be wound immediately after printing. Latex ink is a water-based, odourless solution that produces scratch-resistant prints up to 1200 dpi. The combination of high speed, quality, and fast drying makes this a very efficient method.

Digital metallization / Thermal transfer printing

Digital foil printing (also known as digital metallisation) enables you to apply high-gloss metallic effects to specific areas of your work. Because the process is digital, it works well for both small and bulk jobs and allows rapid reproduction.

This technique produces sharp, scratch-resistant prints on flexible textile substrates, without the deformation sometimes seen in traditional hot-foil stamping. The process typically involves three steps:

- Print the design on the substrate using toner or electro-ink.

- Apply the foil over the pre-printed cloth.

- Remove the carrier film; the metallised media can then be overprinted using digital or conventional printing.

As this is a relatively new technique, there are fewer examples in use. However, we have tested several of our materials and obtained the best results with Finesse (pictured). We recommend testing samples first to ensure optimal outcomes.

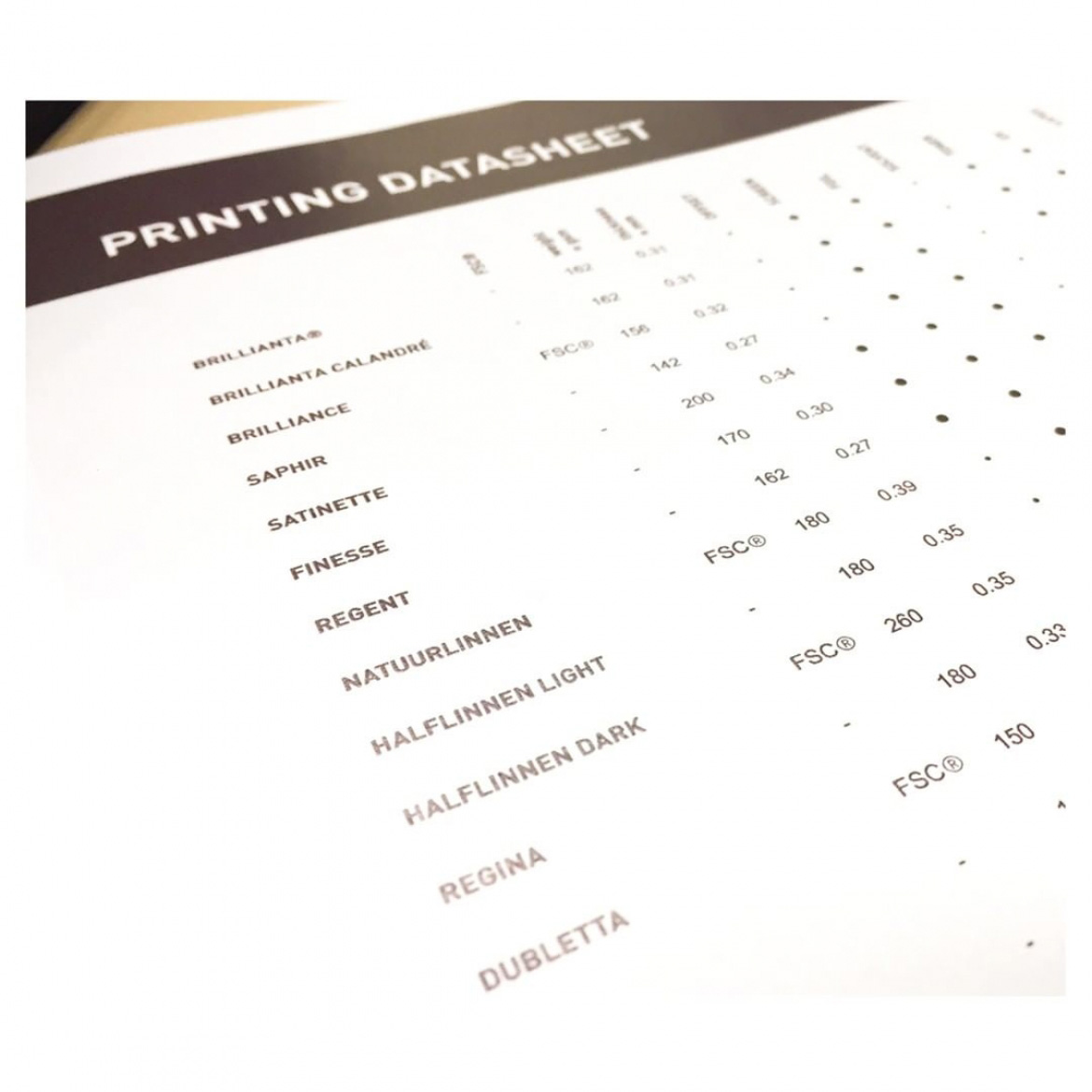

Printing datasheet

Our Printing Datasheet provides a helpful overview of which cover materials are most suitable for specific digital and/or conventional printing methods. You can download it from the Download Centre on our website. We also recommend evaluating your printing results using your own equipment to verify that the quality meets your expectations.